Guadrails

Platform railings are made with the same reliability as stairs

Platform railings are not in a supporting role, but part of the safety and functionality of the whole. We manufacture platform railings that fit into structures, withstand use, and meet requirements without explanations.

Contact usThe same trusted workmanship, also reflected in our railings

Platform railings protect traffic, edges, and platforms, but at the same time they must fit into the surrounding structure. Fastening methods, loads, and operating conditions determine what kind of railing actually works in the project. We approach platform railings as part of the whole, not as a separate addition. Long experience from various projects helps make solutions that are safe to use and easy to implement on the construction site.

How LK Porras platform railings are made

Platform railings are designed according to the project’s requirements and manufactured in our own production facility. The product to be delivered and its fastening method to structures are reviewed according to a clear quality control process before delivery, so that only finished goods go to the construction site.

Modular structure facilitates transportation and speeds up installation. CE-certified operations and documentation are automatically in order and the railing comes into place as planned.

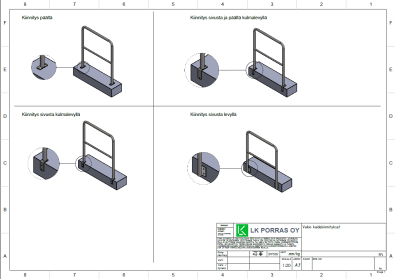

Flexible design also at the quotation stage

3D models of products enable fast progress already at the quotation stage. Illustrative images are included already in the quotation, so the location, height, and structure of the railings are easy to perceive before decisions.

When design is done right from the start, railings don’t cause additional questions or change needs at the final stage of the construction site.

Installation is also handled if necessary. When design, manufacturing, and installation are the responsibility of the same operator, the whole stays under control and the schedule holds.

Platform railings

Welded railings are always made according to the project’s measurements.

Welded rod railing with intermediate rail

Rod railing with intermediate rail. A finger gap remains between the rods and the handrail, where it is comfortable to move your hand. The railing is fastened by bolting to the floor surface, otherwise assembled by welding.

Technical specifications

- Frame pipe d=42.4mm

- Intermediate and bottom rail flat bar 30x5mm

- Rods d=12mm, distance between rods under 100mm

Fastening method and surface treatment

Welded rod railing

Pinnakaide, jossa pinnat menevät yläpaarteseen asti. Kaide kiinnitetään pulttaamalla lattiapintaan, muuten kokoonpantu hitsaamalla.

Technical specifications

- Frame pipe d=42.4mm

- Bottom rail d=26.9mm

- Rods 12mm, distance between rods under 100mm

Welded industrial railing

All welded industrial railings are made according to the project’s measurements.

Technical specifications

- Frame pipe and vertical posts d=42.4mm

- Intermediate rail 28mm

- Kick plate 100mm

- Platform railings can be installed in three different ways depending on the project

- top fastening

- face fastening

- corner fastening

- Surface treatment is hot-dip galvanizing, powder coating according to RAL color chart also possible

- A kick plate can also be added to the industrial railing

LKDS – digital machine shop

LK Porras Design System (LKDS) is our way to make stair design faster and more reliably feasible. It combines design, dimensioning, and production into the same whole, so that solutions don’t just stay on paper.

- Speed: images suitable for the construction site and designers included already at the quotation stage

- Reliability: dimensioning and structures are based on modular solutions

- Smoothness: the plan moves directly to production without unnecessary intermediaries

What do customers say about us?

Gallery