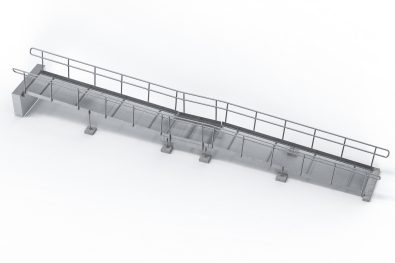

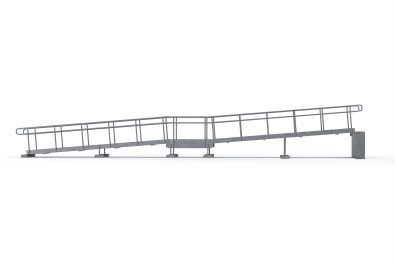

Access ramps

Ramps and wheelchair ramps are made for use

The task of ramps and wheelchair ramps is to make movement smooth and safe for all users. We implement solutions that work in everyday life, withstand use, and meet accessibility requirements without compromises.

Contact usBarrier-free access is functional design

Ramps and inclines are not just an addition to a building, but part of its usability. Gradients, widths, railings, and surfaces determine whether access is really smooth or just compliant with regulations. We approach accessibility through practice. Over 50 years of experience from various projects helps design solutions that work both for users and structures – indoors and outdoors, all year round.

How LK Porras ramps and inclines are made

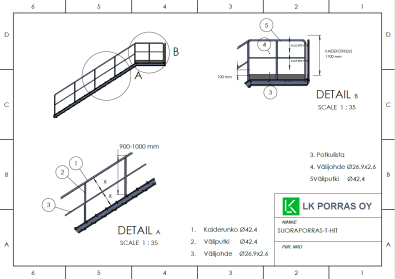

Ramps and wheelchair ramps are designed on the project’s terms and manufactured in our own production facility. Structures, gradients, connections to buildings, and surface solutions are reviewed in a clear quality control process, so that the whole works as planned.

Modular structure enables flexible implementation and speeds up installation even in challenging projects. CE certificate and necessary documentation are in order, and they don’t need to be supplemented afterwards.

Flexible design also at the quotation stage

A 3D model is included already in the quotation, so length, connections, and space requirements are easy to evaluate in time.

When the solution is thought through properly from the start, changes are avoided and it is ensured that access also works in practice – not just on paper.

Installation is also handled with our own crew if necessary. When design, manufacturing, and installation are the responsibility of the same operator, the whole stays under control and the schedule holds.

Ramp and wheelchair ramp frame

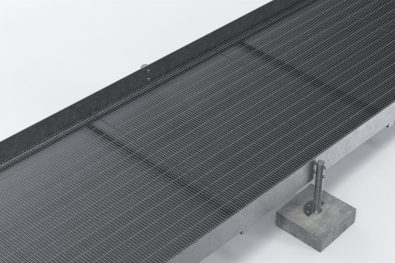

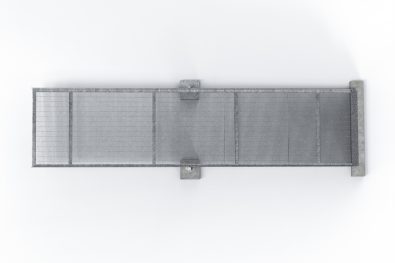

Ramps and wheelchair ramps consist of different parts. All parts are manufactured from steel and are basically hot-dip galvanized to provide the necessary corrosion protection. We manufacture as standard 1000mm and 1300mm wide ramp frames, other widths to order. As standard, ramps have 17×76 grating, but 34×76 grating can be changed to the product. Explore different component options below.

Ramp with 17×76 grating

Basic module, to which, for example, railings or platforms are added if necessary. Grating is dense 17×76. Works both as a base for a wheelchair ramp and for transporting goods.

Technical specifications

Sisältää:

- Ramp frame

- Grating 17×76 anti-slip

- Intermediate supports

U-shaped ramp

U-shaped ramp with landing platform.

Technical specifications

Sisältää:

- Ramp frame

- Grating 17×76 anti-slip

- Intermediate supports

- Railings according to choice

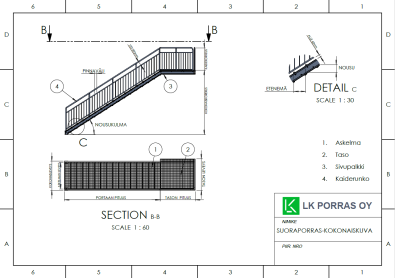

Wheelchair ramp with intermediate platform

Technical specifications

Sisältää:

- Ramp frame

- Grating 17×76 anti-slip

- Intermediate supports

- Railings according to choice

Wheelchair ramp with landing platform. A landing platform is needed for a wheelchair ramp when the ramp length exceeds 6000mm. In this case, the ramp needs a 2000mm long horizontal intermediate platform. Similarly, a long ramp intended for transporting goods must have an intermediate platform where goods can be stopped for a rest.

From the Building Regulations: “The maximum gradient of a ramp referred to in Part F1 of the Finnish Building Code is 8% (1:12.5). The maximum length of the ramp is then 6000 mm, after which a 2000 mm long horizontal intermediate platform is needed. Without intermediate platforms, the ramp gradient may be a maximum of 5% (1:20).”

Ramp railing and handrail options

A wheelchair ramp, or a ramp intended for transporting goods, can be equipped with different railings according to the project’s requirements.

Double handrail railing for wheelchair ramp

Double handrail railing is used when the fall height is less than 500mm. Handrail heights 700 mm and 900 mm.

Technical specifications

- Pipe diameter 42.4mm

- Steel or stainless steel

- Steel handrail is high-quality hot-dip galvanized, no zinc spikes

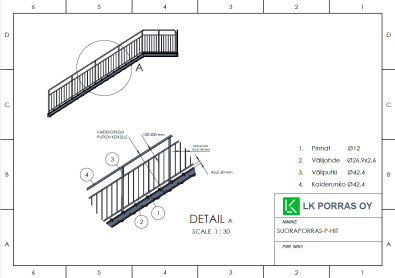

Modular rod railing for wheelchair ramp

According to the project’s requirements, the ramp can be equipped with a modular rod railing. A modular rod railing is an affordable, fast, and attractive option for a ramp railing.

Technical specifications

- Frame pipe d=42.4mm

- Rods 12mm, distance between rods under 100mm

- Handrail d=42.4mm steel

Modular rod railing with double handrail

According to the project’s requirements, the ramp can be equipped with a modular rod railing. A modular rod railing is an affordable, fast, and attractive option for a ramp railing.

Technical specifications

- Frame pipe d=42.4mm

- Rods 12mm, distance between rods under 100mm

- Handrail d=42.4mm steel

Welded rod railing A, with finger gap and additional handrail for wheelchair ramp

Custom-made rod railing is manufactured specifically for your project.

Technical specifications

- Frame pipe d=42.4mm

- Rods 12mm, distance between rods under 100mm

- Handrail d=42.4mm steel or stainless steel

Welded rod railing A, with finger gap and additional handrail for wheelchair ramp

In this rod railing, the rods go all the way to the top beam of the railing, without a finger gap.

Technical specifications

- Frame pipe d=42.4mm

- Rods 12mm, distance between rods under 100mm

- Handrail d=42.4mm steel or stainless steel

Surface treatment and additional information

Ramps and inclines are basically always hot-dip galvanized as standard. Choose the color of your ramp’s handrails according to the project.

- Surface treatment as standard is hot-dip galvanizing

- Handrail surface treatment is hot-dip galvanizing, painting in RAL color chart shades also possible

- In painted parts, fasteners are hot-dip galvanized/stainless steel

- Painted products are standard in semi-gloss shade, unless otherwise agreed

- The surface of hot-dip galvanized and painted products is not completely smooth, so please take this into account when ordering the product

LKDS – digital machine shop

LK Porras Design System (LKDS) is our way to make stair design faster and more reliably feasible. It combines design, dimensioning, and production into the same whole, so that solutions don’t just stay on paper.

- Speed: images suitable for the construction site and designers included already at the quotation stage

- Reliability: dimensioning and structures are based on modular solutions

- Smoothness: the plan moves directly to production without unnecessary intermediaries

What do customers say about us?

Gallery